Duct Corner Punching Machine

Duct Corner Punching Machine

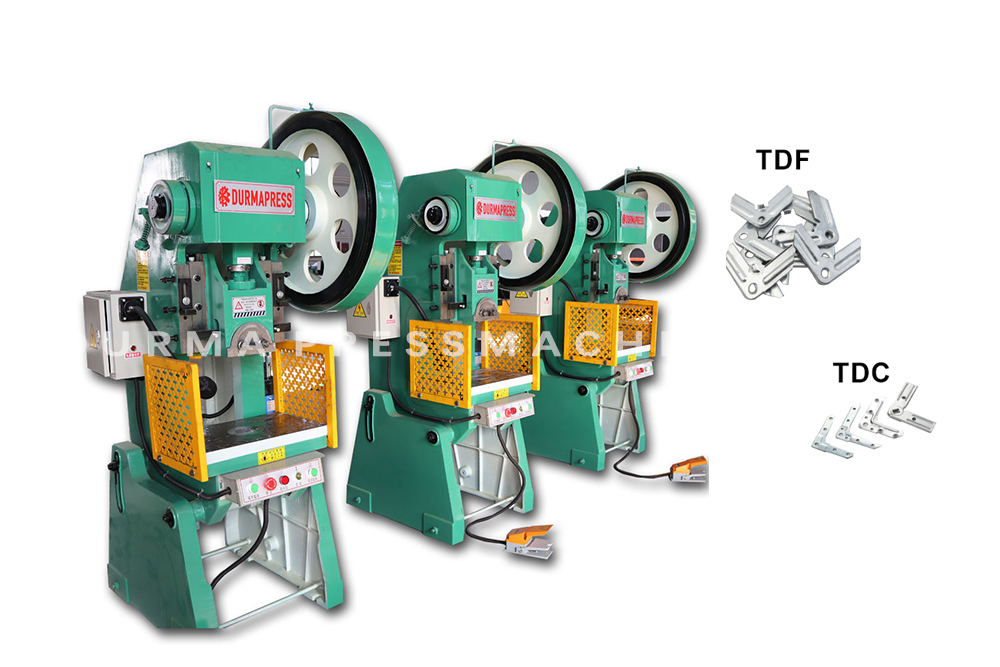

Corner forming machine is mainly for punching, blanking, folding, cutting, and light stretching work.

Basic Information

We also called duct flange corner production machine, which can produce TDF corner or TDC corner with one time forming die. This kind of corner equipment has been accepted by more and more clients. Also, high production efficiency is the most important for the present ducting business. This type TDC or TDF duct flange corner making machine is specially suitable for the duct manufacturers with many years of experience in this ducting industry. Just to change the TDC flange corners progressive moulds or TDF flange corners progressive moulds to obtain these two corners.

The whole TDC / TDF duct flange corner production machine consists of de-coiler, material feeding device, punching machine with Progressive Corner Moulds, etc.

Final Products

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power

TECHNICAL DATA

TEMS | UNIT | J23-6.3 | J23-10 | J23-16 | J23-25 | J23-35 | J23-40 | J23-63 | JB23-63 | J23-80 | J23-100 | J23-125 | |

Capacity | KN | 63 | 100 | 160 | 250 | 350 | 400 | 630 | 630 | 800 | 1000 | 1250 | |

Nominal stroke | mm | 2 | 2 | 2 | 2.5 | 3.5 | 6 | 6 | 7 | 7 | 7 | 8 | |

Slide stroke length | mm | 35 | 45 | 55 | 65 | 80 | 90 | 110 | 110 | 120 | 140 | 150 | |

Stroke times per minute | spm | 170 | 145 | 125 | 55 | 50 | 45 | 50 | 40 | 38 | 38 | 38 | |

Max. Die set height | mm | 150 | 180 | 220 | 270 | 290 | 320 | 360 | 390 | 440 | 480 | 500 | |

Die shut height adjustment | mm | 30 | 35 | 45 | 55 | 60 | 65 | 80 | 80 | 90 | 100 | 100 | |

Throat depth | mm | 110 | 130 | 160 | 200 | 220 | 250 | 260 | 310 | 350 | 380 | 390 | |

Distance between uprights | mm | 150 | 180 | 220 | 270 | 280 | 340 | 350 | 420 | 450 | 560 | 550 | |

Slide bottom size | L-R | mm | 140 | 170 | 200 | 250 | 250 | 300 | 300 | 400 | 430 | 540 | 540 |

F-B | mm | 120 | 150 | 180 | 220 | 220 | 260 | 260 | 360 | 360 | 480 | 480 | |

Stemhole size | Diameter | mm | 30 | 30 | 40 | 40 | 40 | 50 | 50 | 50 | 60 | 60 | 60 |

Depth | mm | 55 | 55 | 60 | 60 | 60 | 70 | 70 | 70 | 75 | 75 | 75 | |

Bolster size | L-R | mm | 310 | 370 | 450 | 560 | 610 | 700 | 760 | 860 | 950 | 1080 | 1100 |

F-B | mm | 200 | 240 | 300 | 370 | 400 | 460 | 480 | 570 | 650 | 710 | 720 | |

Thickness | mm | 30 | 35 | 40 | 50 | 60 | 65 | 80 | 80 | 100 | 120 | 130 | |

Table hole diameter | mm | 60 | 80 | 100 | 120 | 130 | 150 | 180 | 180 | 200 | 220 | 240 | |

Max. inclinable angle | ° | 45 | 35 | 35 | 30 | 30 | 30 | 20 | 20 | 20 | 15 | 13 | |

Bolster surface height | mm | 750 | 730 | 750 | 800 | 815 | 850 | 810 | 850 | 850 | 850 | 860 | |

Over all dimensions | L-R | mm | 620 | 665 | 847 | 950 | 1058 | 1335 | 1350 | 1500 | 1715 | 1790 | 1790 |

F-B | mm | 780 | 900 | 1150 | 1345 | 1460 | 1721 | 1810 | 1958 | 2060 | 2404 | 2504 | |

Height | mm | 1503 | 1658 | 1910 | 2130 | 2225 | 2488 | 2740 | 2868 | 3290 | 3625 | 3715 | |

Distance between foundation bolts | L-R | mm | 314 | 394 | 450 | 600 | 650 | 750 | 850 | 920 | 1010 | 1130 | 1110 |

F-B | mm | 530 | 610 | 780 | 920 | 1020 | 1060 | 1180 | 1300 | 1360 | 1550 | 1710 | |

Motor power | kw | 0.75 | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | |

Weight | kg | 400 | 576 | 1085 | 1780 | 2650 | 3540 | 4550 | 5500 | 7390 | 10800 | 12035 | |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.