CNC Plasma Cutting Machine

CNC Plasma Cutting Machine

CNC plasma cutting machine is mainly for automatically lofting and cutting the deformed workpiece. The machine adopts the latest CAM-DUCT PM 2000 software and the software combines technology, data procedure with management.

- It’s convenient, accurate, and practical

- With dedicated control system, the function is more stable

- Can automatically generate drawings and output processing procedures

Features:

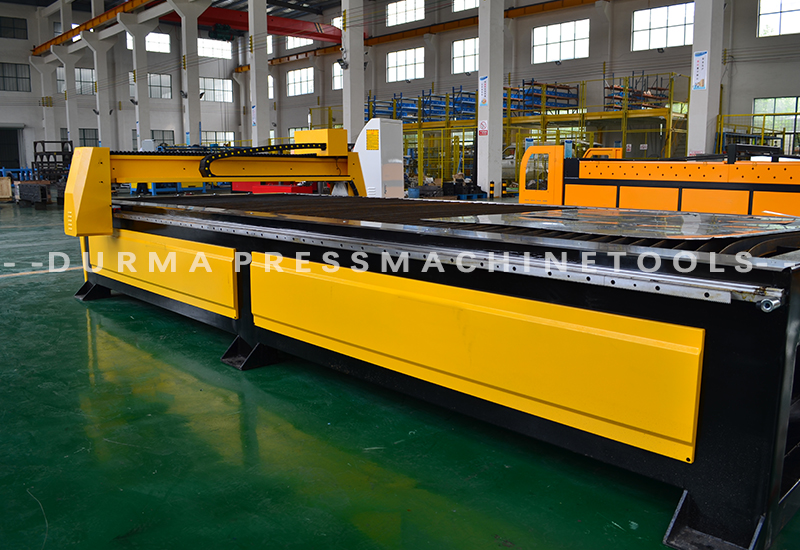

1. Welded structure of thickening square tube, together with top brand guide rail to ensure high running speed and accuracy.

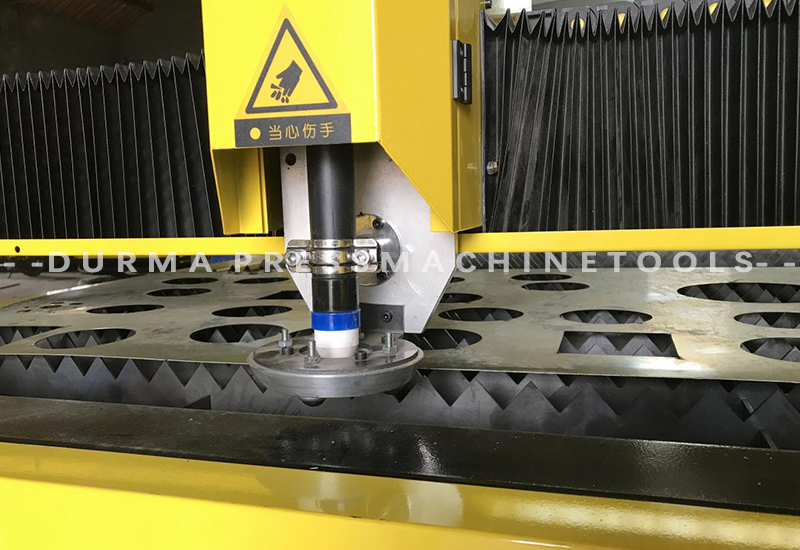

2. Hypertherm plasma power supply together with high sensitive arc pressure adjuster. Self-adjusting can choose the best distance between plasma gun and working piece automatically to ensure high accuracy cutting.

3. High definition CNC pasma cutter for sheet metal uses STARFIRE control system with FastCAM software for auto material saving function, large capacity storing function, convenient to read and process.

4. Cutting head with cooling system can quickly cool surface of material to avoid burr and residue.

5. Overall stepper motor with high precision rack and pinion, to ensure the cnc plasma cutter has small noise, smooth, precise coordinates of the mobile performance.

6. Perfect software compatibility, such as Ucancam, Type 3, Artcum, etc.

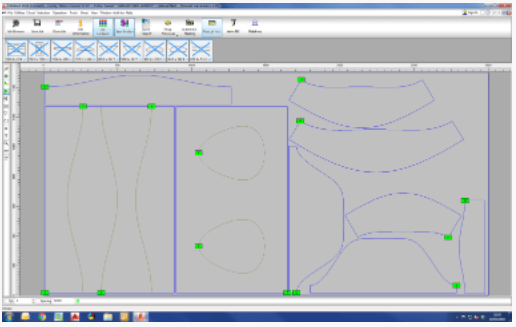

CNC Plasma Cutting Machine Software:

The machine adopts the latest CAM-DUCT software from Auto Desk company and the software combines technology, data procedure with management and meets cutting requirements of duct workplace by using pre-designed standard duct drawings and parameter settings. The software is easy to learn and operate because it only requires machining dimensions to develop an unfolded view of deformed duct automatically.

Automatic plasma cutting machine is mainly for automatically lofting and cutting the deformed workpiece. You can select a drawing from the new version of CAM-DUCT and input dimensions and choose a way of connection, then the software will start calculating, composing, jacking, and cutting automatically according to your requirements.

The touchscreen of this machine is a vertical control cabinet with a 10-inch touchscreen. Besides, the automatic plasma cutting machine includes a PM200 control system and a HUAYUAN generator. With the widely praised CNC cutting special control system, the function is more stable and easy to operate.

With a unique height adjusting device for cutting walls, this machine can avoid the sticky plate phenomenon between the cutting head and iron sheet. What’s more, rolling friction can make the operation more stable and the cutting speed is improved to a great extent. We adopt dedicated air duct expansion software. It can automatically generate drawings and output processing procedures.

The operator needs to choose duct shape in software and input dimension, then the machine will cut sheet metal automatically. It’s convenient, accurate, and practical. The CNC plasma cutting machine is mainly used to cut the sheet metal for the HVAC ventilation duct, so the suitable sheet metal thickness is 0.4-4 mm galvanized sheet. For stainless steel, the max thickness is 2 mm. The machine mainly consists of the main machine, generator, and CNC control system. About the generator, our standard is the HUAYUAN brand, but we can also assemble a Hypertherm generator for you.

For after-sales service, we have skilled technicians who can teach you how to operate machines via video. Besides, engineer overseas service is available.

CAM-DUCT Software :

1. Processor: using industrial grade ARM processing chip;

2. Display: 7-inch color LCD, 800*480;

3. Input\Output: The system provides 16 channels of photoelectric isolation input and 16 channels of photoelectric isolation output;

4. Number of linkage axes: 2 axes, which can be expanded to 3 linkage axes;

5. Maximum speed: not less than 24 m/min;

6. Pulse equivalent: flexible adjustment;

7. Storage space: 4G large user program storage capacity, unlimited processing programs;

8. Chassis size: 298×202×65(mm);

9. Working temperature: 0℃~+40℃;

Storage temperature: -20℃~+60℃;

A full re-write of CAMduct’s nesting algorithms has just been completed, making the automatic nesting function produce less waste and have the best productivity. CAMduct’s Green Nesting improves sheet utilisation and sheet management.

Fabrication CAMduct has the most comprehensive and proven fitting libraries ready to use. Round, rectangular, and oval fittings, which are suitable for seamed or welded construction, are fully parametric and highly customisable.

Plasma Power Optional :

Hyptherm Power

Huayuan Power

Final Products

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power

TECHNICAL DATA

Name | Parameters | Unit |

Processing Area | 1500*3000 | mm |

Processing Materials | Iron, aluminum, galvanized sheet,white sheet, |

|

Processing Thickness | 0.1-15 | mm |

Cutting Speed | 0-8000 | mm/min |

Input Voltage | 380V/50hz/3ph or other | V |

Plasma Current | 160 (Chengdu Huayuan Brand) | A |

Cutting Thickness | 0-15(Mild Steel) | mm |

Control System | SF-2012AH (camduct software) |

|

File Transfer Mode | USB interface |

|

Work | Non-contact arc |

|

Reposition Precision | ±0.05 | mm |

Processing Precision | ±0.1 | mm |

Dimension | 4600*2200*1480 mm | mm |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.