Hydraulic Elbow Making Machine

Hydraulic Elbow Making Machine

Hydraulic round duct elbow making machine is for producing round elbows in ventilation & air conditioning system. With hydraulic power to ensure higher capacity and better speed for spiral round duct.

Features:

This machine is a cost-effective solution for the production of welded elbows, reducers, end caps and off-sets for HVAC, downspout and exhausting systems. Low power consumption, easy operating and adjustment provides you the power to fabricate hundred of fittings instore per day.

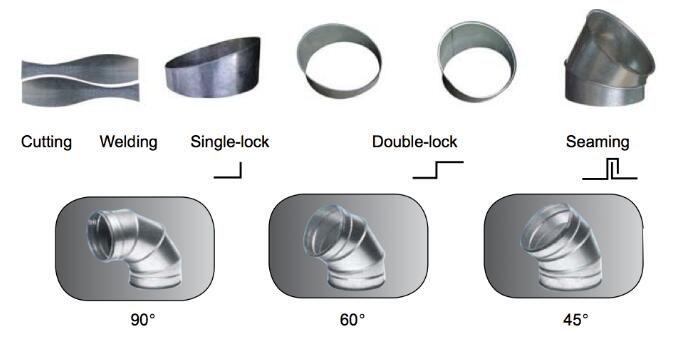

It’s a two side machine with two separate working sites. One side is a Flanger/Swager to flange one side of a cylindrical gore. On the same side by switching mode crank – upper table goes dawn and operator is swaging the connecting side of the next gore. On the second side (opposite end) of the machine (lock seam clsoser side), at the same time another operator finalizes the operation by closing the seam into a standing rib.

- Dual workstation, maximum flexibility to eliminate changing over

- Higher production speed to ensure higher flanging speed

- Optimised roller’s profile, improved seamed quality

- All rotating parts are hardened and high-grade steel, virtually maintenance

Function:

There are two worktables: worktable height can be adjustable, which is easy for changing the male and female opening. Roller has a hydraulic motor drive, adjustable speed, roller forward and backward also use cylinder drive, smooth and efficient working performance.

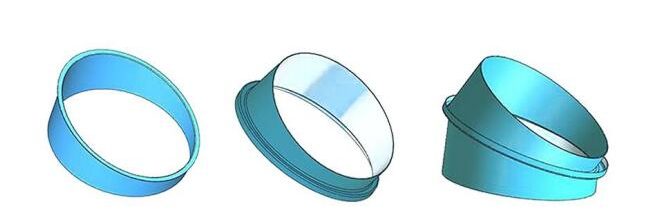

Working Schematic Diagram:

There are two stations on the gorelocker -elbow lock forming station and elbow seam locking station. All these two stations are driven by independent hydraulic oil tank!

That makes the machine running automatically, accurately and at a very fast speed of max. 120m/min. This hydraulic duct elbow forming machine handles a variety of duct materials and gauges to make elbows from 5″-50″ or 125mm-1250mm.

The materials it supports are black steel, galvanized steel, stainless steel, aluminum and etc.

Hydraulic elbow making machine is the only equipment that can connect the round duct and can adjust the wind tube bending direction arbitrarily, and the working diameter is 100 mm~1250 mm, although the machine is large, the motor power just 4 kw, this means that the machine is very energy efficient, this is the biggest surprise for customers in need.

Hydraulic elbow making machine is also used for interface modeling and commissure of shrimp elbow tube, also elbow machine for spiral round duct is for producing round elbows in ventilation & air conditioning system. With the hydraulic power to ensure higher capacity for spiral round HVAC air duct.

Final Products

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power

Shipping & Packing

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

TECHNICAL DATA

1 | Diameter | 100-1250mm |

2 | Thickness | 0.4-1.2mm |

3 | Mini dia | 100MM |

4 | Rolling speed | 120m/min (Adjustble) |

5 | Suitable material | Galvanized steel, stainles steel,aluminum steel |

6 | Main motor power | 4KW+120W (cooling fan) |

w | Hydraulic oil | 55L |

8 | Air compressor | 0.8MPa |

9 | Dimension | 2700×700 x 1200mm |

10 | Weight | 760K |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.