Angle Steel Round Rolling Machine

Angle Steel Round Rolling Machine

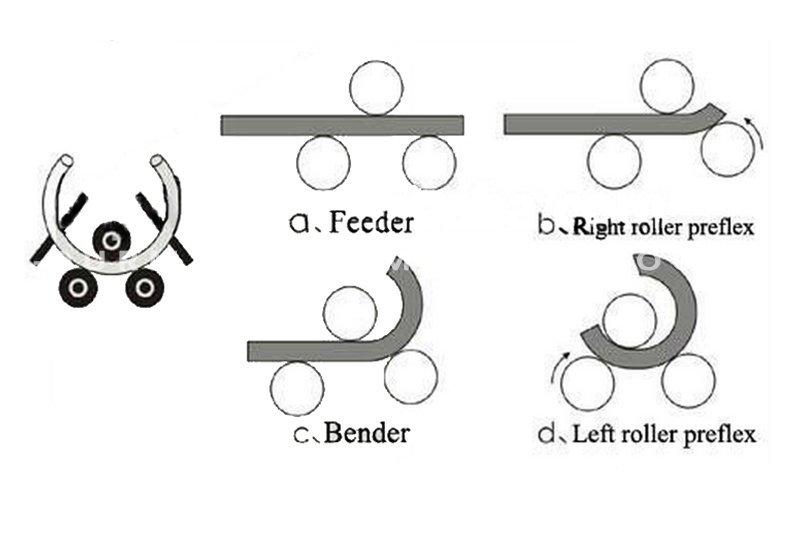

The angle steel round rolling machine is an indispensable equipment for producing round duct, it allows the circular duct to be well connected, and this machine work with the hydraulic riveting machine to connect a good round duct will never fall off. At the top of the machine, there is a rotating lock that resizes the size, This is used to adjust the diameter of the ring, the maximum diameter of angle steel round rolling machine is 400mm

Basic Information

It’s used for rounding angle steel flange and 40Cr steel with overall heat treatment makes the machine more durable, JY-50 series angle steel round rolling machine can be changed according to different needs. You can roll angle iron, flat iron, square steel pipe, steel, etc. Three roll gap can be adjusted to work, saving material. It’s widely used in construction, fitment, hardware, light industry and chemical industries. And this machine is a high benefit roll round device

The structure has the advantages of small size, low energy consumption, high efficiency and no noise, the installation and use are convenient, the operation is simple, the carrying capacity is strong, the service life is long, the rolling speed is fast, the product quality is reliable and steady.

Basic Configuration:

- One motor

- One electronic box

- One control electric system

- One set mold

- One cylinder

Shipping & Packing

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

TECHNICAL DATA

Model | Lield limit(mm) | Min diameter(mm) | Max capacity(mm) | Power(kw) | Weight(kg) | Dimensions(mm) L*W*H |

JY-50 | ≦245 | 400 | L50*5 | 3 | 350 | 760*780*1150 |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.