Auto Duct Production Line

What is Auto Duct Production Line ?

The HVAC Auto Duct production line is that the entire process of air duct forming is completed by one machine independently. To put it simply, the whole process from coil blanking to air duct forming is continuously and independently completed by machine processing equipment. The intermediate process does not require anyone’s participation and operation.

How to form a complete air duct production line?

Let’s take a look at the specific needs to achieve the following functions:

1. Coil material selection and cutting function; 2-6 different thickness or material coils can be selected.

2. The function of pressing and flattening; this function is the adjustment process before the processing of the coil to prevent waste.

3. Punching, chamfering and grooving functions; this function can complete the production of air duct installation holes and avoid the inconvenience caused by later punching.

4. Cutting function; this function separates the sheet material from the coil material for the next processing.

5. Transmission function; it is convenient for the coil material to automatically carry out the processing of the next process.

6. Bite; this function realizes the pressing operation of the sheet and makes the joint angle.

7. Common plate flange forming; this function is a key step in making double-sided common plate flanges.

HVAC Auto Duct Production Line

Durmapress® company will provide customers the most suitable machines according to customers needs. Besides, we can also customize machines on the basis of your special requirement.Durmapress® company specializing in the production of CNC auto duct line machine, Specifically for HVAC pipeline processing practitioners to provide professional processing equipment and perfect after-sales service. For many years, the CNC auto duct line machine is the most efficient products in the duct/pipe processing industry, we provide high-quality products to clients around the world with strong technical strength and years of production experience.

Features of Auto Duct Production Line:

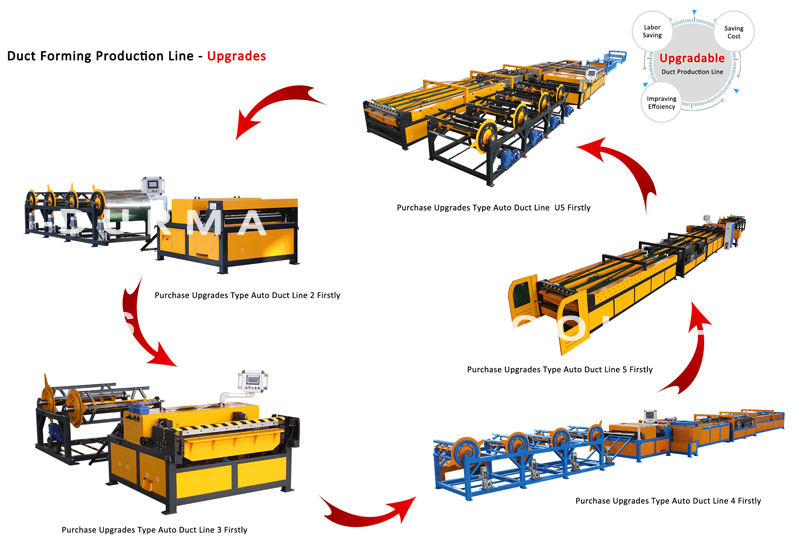

- U shape auto duct production line 5: With fast processing speed, this machine needs smaller floor area than linear auto duct production line 5. Functions are same as linear auto duct line 5.

- Linear auto duct production line 5: This linear machine can process sheet coil, including leveling, grooving/beading, angle shearing, cutting, Pittsburgh lock forming, TDF flange forming and folding.

- Auto duct production line 4: This machine can complete all processing steps before duct folding, including leveling, grooving/beading, angle shearing, cutting, Pittsburgh lock forming and TDF flange forming.

- Auto duct production line 3: The line 3 machine can finish sheet leveling, grooving/beading, angle shearing, cutting and folding with CNC automatic system. Faster and more convenient.

- Auto duct production line 2: This line 2 machine has 4 functions, including leveling, grooving/beading, angle shearing, and cutting. It’s more economical.