AUTO DUCT LINE III

首页 » AUTO DUCT LINE III

Auto Duct Production Line

- U Shape Auto Duct Production Line V

- Auto Duct Production Line V

- Auto Duct Production Line IV

- Auto Duct Production Line II

- Auto Duct Production Line III

- Contact Us

Brand: DURMAPRESS

Function

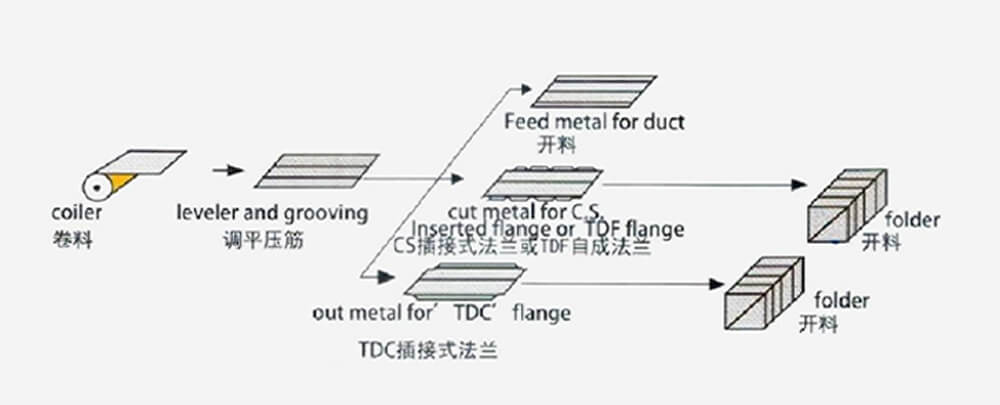

- It mainly completes the unwinding, leveling, rib pressing, corner punching and single and double joint processing of coils. The production line occupies a small area, is easy to assemble and convenient for on-site construction. It can be upgraded to a super four-line.

- Duct production line 3 can realize automatic duct unloading and is also very suitable for diversified production such as TDF/angle steel/insert flange. Angle steel flange and insert flange can be automatically bent into square tube.

- The three-line bending function can directly bend the small edge, and can stably process 0.5-1.2mm thick galvanized sheets to avoid waste.

Duct production line 3 can drive blanking for duct. Meantime, it’s very suitable for diversified production like TDF/angle steel/inserted flange forming; the angle steel flange and inserted flange can be bent into square-shaped pipe automatically.

All rolling wheels are made of bearing steel, and the service life is increased by more than 5 times.The CNC system adds a material saving mode, and each task can automatically return the material.With production memory function, it has the function of querying production orders.

It mainly completes the unwinding, leveling, rib pressing, corner punching, and single and double joint mouth processing of coils. The production line occupies a small area, is easy to combine, and is convenient for on-site construction. It can be upgraded to super four-line use.

The basic configuration includes an electric coil rack, 2 material trays (5-7 tons per roll), a support rack, one host (line 3 host), a manipulator material grasping positioning and conveying platform, a displacement type locking machine, and a computer control system.

In addition, in addition to the basic configuration, DURMAPRESS also provides optional imported configurations to meet the needs of different customers. You can choose the original imported cylinder from Germany Festo, Beijing Huade + Taiwan hydraulic system, Japan Omron (OMRON) special encoder, Taiwan Hiwin (HWIN) linear guide, Schneider electrical system.

- German Festo (FESTO) imported cylinders

- Japanese Mitsubishi CNC system Schneider electrical system

- Beijing Huade or Taiwan hydraulic system

- Japanese Omron (OMRON) encoder

- Taiwan Hiwin (HWIN) linear navigation

- One electric coil rack, two material trays (5-7 tons per roll)

- One support rack

- One host (line 3 host)

- One manipulator material grabbing positioning and conveying platform

- One displacement type locking machine

- One computer control system

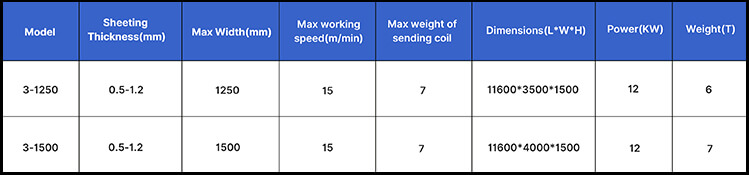

- Technical Data

- Production Details

Machine Frame

The machine frame adopts welding square steel,annealing treatment and overall processing to ensure the stability and flatness of the frame and processing accuracy.

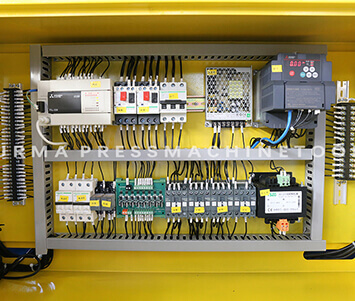

Control System

Support multiple languages, stable system, simple operation, fully automatic or manual optional, more convenient for HVAC production operation.The CNC system adds a material saving mode, which can automatically return materials for each task.

Corner Cutting Mold

The corner cutting mold is made of cost-effective manganese steel, which can process 1.5mm thick plates. The high-pressure oil pipe is made in Taiwan and is durable.

Electric System

Control system mainly use Mitsubishi PLC and driver, but Schneider PLC and driver is also optionally.

.jpg)

Electric coil rack

DURMAPRESS Auto line III includes an electric coil stand with 2 trays and a maximum coil weight of 7 tons.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us