AUTO DUCT LINE Ⅴ

首页 » AUTO DUCT LINE Ⅴ

Auto Duct Production Line

- Auto Duct Production Line II

- Auto Duct Production Line III

- Auto Duct Production Line IV

- U Shape Auto Duct Production Line V

- Auto Duct Production Line Ⅴ

- Contact Us

Brand: DURMAPRESS

Function

- Main functions: Complete the forming of common plate flange, angle steel flange or "C" type flange.

- Processing capacity: Daily processing capacity 600 - 2000 square meters.

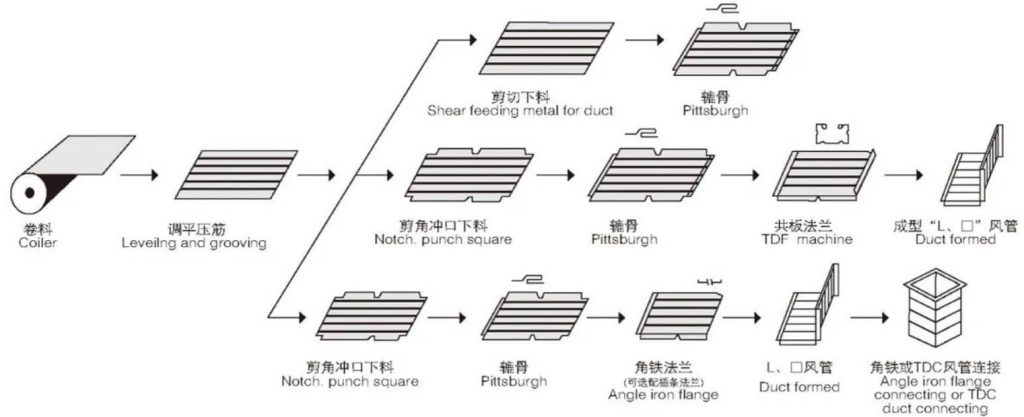

- Automatic operation: After inputting the duct size, the production line automatically completes uncoiling, leveling, rib pressing, corner punching, shearing, joint biting, common plate flange/angle steel flange forming or "C" type flange forming, and folding forming.

With production management functions: Day Count, Cumulative Count. Separate two kinds of inputmodes (touch screen and physical keyboard) ensure operation reliability greatly.

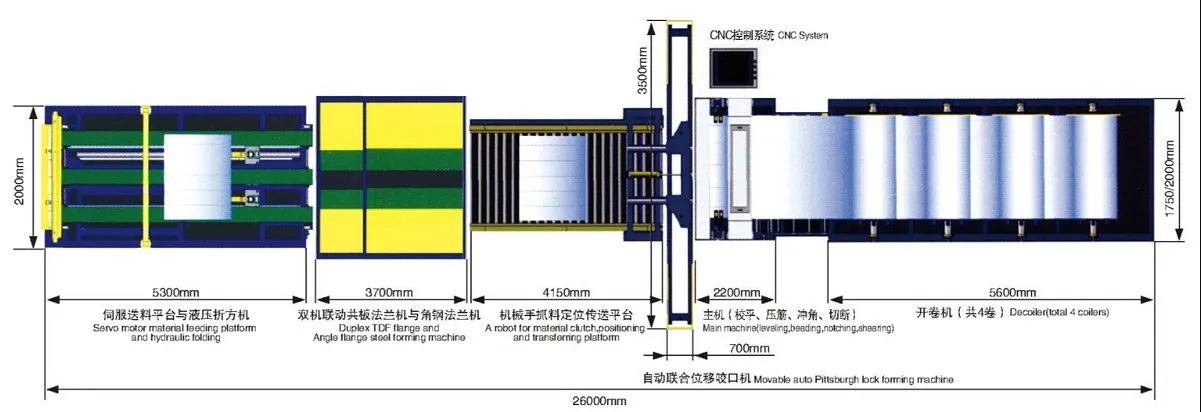

Durmapress auto duct line 5 is a multi-functional main body with a host duct line 2 ,one mechanical armclutching, locating and transferring platform, one displacement type locking machine, one duplex TDF flange forming machine, one duplex angle steel flange forming machine, one servo feeding platform,one hydraulic folding machine, one set of computer controlling system.

1.The latest design can resolve the problems like getting struck, too many repairs form roll-shearing displacements lock machine.

2.The three-line bending function can crimp narrow edges and stably process 0.5-1.2mm galvanized sheet to avoid wasting.Mechanical arm clutching, locating and transferring platformDisplacement lock machineLine 3 host+ Single rackll.II .

3.The linear structure of machine makes processing smoothly and occupies a small space.

4.All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

5.Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

6.The locating system is very accurate with servo feeding mechanism, especially when processing square-shaped pipes.

7.It’s equipped with 10 inch LCD touch screen and optional dual keyboard mode to keep operation stable.

8.It requires at least one person to operate and each shift can output 600-2000.

9.With production memory functions, the production orders can be tracked and checked.

- Cylinder imported from Germany Festo

- Mitsubishi CNC control system

- Japan Omron encoder

- Taiwan Hiwin linear guideways

- Schneider electrical system

- Two electric coil cradles, 4 material trays (5-7t each roll)

- One rack

- One host (line 2 host)

- One mechanical arm clutching, locating and transferring plateform

- One displacement type locking machine

- One duplex TDF flange forming machine

- One duplex angle steel flange forming machine

- One servo feeding platform

- One hydraulic folding machine

- A set of CNC computer control system and production software

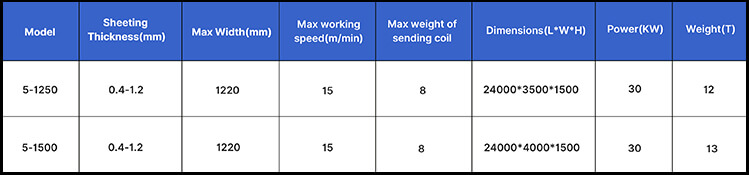

- Technical Data

- Production Details

Machine Frame

The machine frame adopts welding square steel,annealing treatment and overall processing to ensure the stability and flatness of the frame and processing accuracy.

PLC Control

Use Germany Siemens PLC controller which can accurately control the machining length,particularly suitable for production of ”L” and”口“-shaped pipe with different size.

Decoilers

Double coilers with adjustable coiling diameter of 500-600mm, loading capacity of each coiler reaches to 7T, driven by high-performance motor and reducer, which significantly improve

the practicability of coiler.

Loading Feeder

The upper loading feeder is supported with a rubber bearing to prevent the plate surface from cratching, and the ight and left sides are equipped with adjustable supporting arms.

Feeding Inlet

The feeding inlet is provided with a secondary feeding guiding rack to ensure feeding accuracy and improve its property against deviation.

Angle notching

Notching”V””口”groove, the dies are made by Cr12Mov material with longer service life. Cutting angle and depth are adjustable, convenience for production.

Sheet Cutting

Cutting method: holding-down on up side,hydraulic transmission, the blade is made by 6CrW2Si steel that can cutting stainless steel,cutting thickness within 0.5-1.2mm.

Square Duct

The Stainless steel duct production V line is mainly used for rectangular duct production, from coil material to duct finished product, assembly line operation, fully automated production; advanced technology, high degree of automation, and high production efficiency.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us