Round Duct Lockformer Machine

Round Duct Lockformer Machine

Locking machine is necessary in duct area because it can produce all kinds of types to meet locking requirements. Standard machine can process 0.5-1.5mm galvanized sheet metal, and our company would specially introduce high-strength rolling reels made of GCr15, a kind of steel which prolongs the machine life by more than 5 times and improve the efficiency dramatically.

- It can form 6 shapes (7-function is available) to finish sheet connection

- We can customize the S shape and snap-lock for sheet locking

- GCR15 steel can prolong the machine life by more than 5 times

Basic Information

Lock forming machine is a necessary equipment for HVAC air duct manufacturing. Multi-function lock forming machine can form 6 shapes (7-function is available) to finish sheet jointing. Six shapes include Pittsburgh(Female), Right angle(Male), Standing seam, C shape locking pin, Curving angle and Z shape. What’s more, we can customize S shape and snap lock for sheet locking. The standard machine can make 0.5-1.5 mm thickness galvanized sheet. The lock forming machine usually has two model, one’s max thickness is 1.2 mm, another’s max thickness is 1.5 mm. Our company specially introduce high-strength rolling reel made of GCR 15 steel which can prolong the machine life by more than 5 times and greatly heighten the efficiency. The lock forming machine can be divided into two types according to duct shape. One type is square duct lock forming machine, for example, 6-function lock forming machine. Second is round duct lock forming machine, for example, longitudinal seam connection lock forming machine. The square duct lock forming machine is a part of rectangular ventilation air tube forming machines, it can be used with other rectangular HVAC duct forming machines together to achieve a whole duct production, such as TDF flange forming machine, pneumatic TDF sheet metal folding machine, grooving machine, electric cutting machine, square duct lock seam closing machine, clips cutting machine, etc. The round duct lock forming machine can be used with the electric rolling machine, round duct lock seam closing machine, bead roller and so on.

Description:

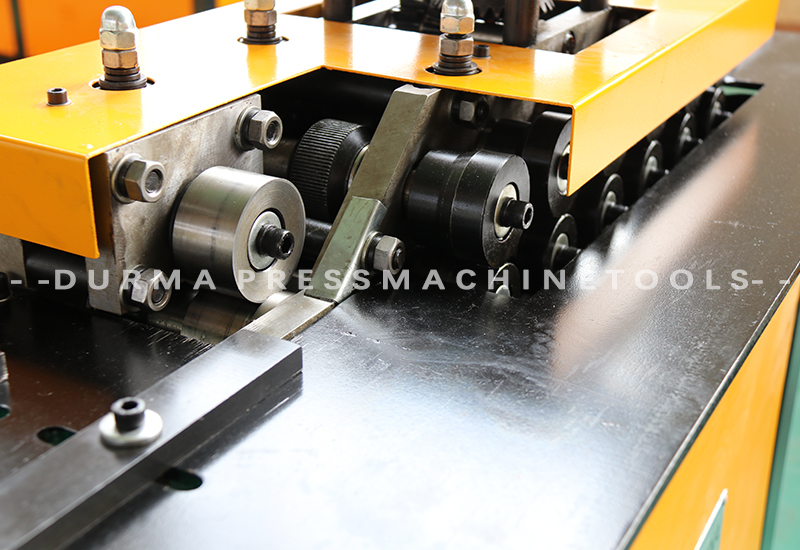

The lock forming machine also named pittsburgh lock former or pittsburgh rolformer.The machine is mainly used in the production ofHVAC air ducts for round duct making and is one of the most basic production equipment.

The lock forming machine can make 2 kinds of different duct shapes for suiting round duct seaming.This is a multifunctional machine.The desired shape can be produced by two sides.

Lock forming machine/Pittsburgh lock former type is SA-15C.

The SA-15C is using high quality GCr15 steel rollers, the locks formed are nice and clean with the joint be tight and firm.

Basic Configuration:

1.2 stations available on the machine as per the following,1.Claw shape 2.”U” shape

2.380V/50HZ/3PH is the regular standard Voltage for our lock forming machine.Yet we can manage them into 220V/50HZ/1PH or 420V/50HZ/3PH and etc.Cost will be free of charge as a cooperation to our international customers!ll

3.Preda Machine provides rollers and axles changing the whole life time of the machine

4.Customized roll forming flange size and shape can be achieved by Preda Machine in case required.

Shipping & Packing

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

TECHNICAL DATA

Model | Max sheet thickness (mm) | Power (kW) | Shape | Weight (kg) | Dimension L*W*H (mm) |

SA-12HB | 1.2 | 1.5 |

| 230 | 1070*570*920 |

SA-15HB | 1.5 | 3 | 350 | 1200*650*1050 | |

SA-12B | 1.2 | 1.5 |

| 220 | 1070*570*920 |

SA-15B | 1.5 | 3 | 340 | 1200*650*1050 | |

LS3 | 1.2 | 2.2 |

| 360 | 1500*640*960 |

XFA-1.0 | 1.0 | 2.2 |

| 350 | 1400*620*950 |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.