Electric 3 Roller Rolling Bending Machine

Electric 3 Roller Rolling Bending Machine

Pre-bending function makes straight edges narrower, and it can even round small round pipe with diameter of 100mm. Combined with manual worm gear and eccentric wheel device, the machine can quickly move side rollers up and down to improve efficiency.

Basic Information

The pre-bending function makes straight edges narrower, and it can even round small round pipe with a diameter of 100mm. It can cooperate with the round duct locking machine and the round duct lock seam machine to produce the round air duct. Combined with the manual worm gear and eccentric wheel device the machine can quickly move side rollers up and down to improve efficiency.

This rolling machine has a precise divided mechanism structure to ensure the synchronization of the three rollers when working at the same time. The bottom and the side roller’s vertical movement is controlled by lifting screw to achieve rolling with the different diameter. Round duct processing machine includes electric rolling machine, round duct lock forming machine, round duct lock seaming machine and round duct grooving machine. All these machines can make a complete round air duct.

Basic Configuration:

- One motor

- One electronic box

- One electric control system

- Four pulley

Machine Frame

The machine frame adopts welding square steel,annealing treatment and overall processing toensure the stability and flatness of the frame and processing accuracy

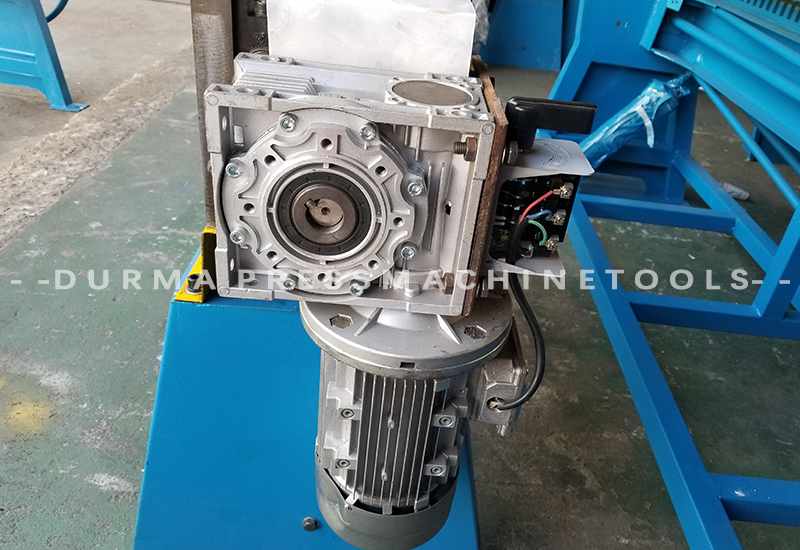

Motor and Reducer

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power

Main Features

(1) Side of the workpiece before use in the pre-bending machine for bending to the effective point of view (when the original

board processing)

(2) To make the next roll rotation, bring materials on board with the rotating roll, the sheet metal rolled into the arc.

(3) The motor for positive and negative movement, and gradually roll on the pressure, repeatedly, thereby enabling the

workpiece gradually forming to requirements.

(4) Taking out the workpiece from the rolling roller.

Final Products

Choose advanced mechanical design technology, the motor and reducer are integrated to reduce the loss of transmission power

Shipping & Packing

Each Electric 3 Roller Rolling Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

TECHNICAL DATA

Model | Max thickness(mm) | Max width(mm) | Min diameter(mm) | Power(kw) | Weight(kg) | Dimensions(mm) L*W*H |

W11-2*1000 | 2 | 1000 | 100 | 1.5 | 240 | 1400*600*1100 |

W11-1.5*1300 | 1.5 | 1300 | 100 | 1.5 | 260 | 1700*600*1100 |

W11-1.5*1500 | 1.5 | 1500 | 100 | 1.5 | 280 | 1900*600*1100 |

Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

Durmahvac is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.