AUTO DUCT LINE IV

首页 » AUTO DUCT LINE IV

Auto Duct Production Line

- U Shape Auto Duct Production Line V

- Auto Duct Production Line V

- Auto Duct Production Line II

- Auto Duct Production Line III

- Auto Duct Production Line IV

- Contact Us

Brand: DURMAPRESS

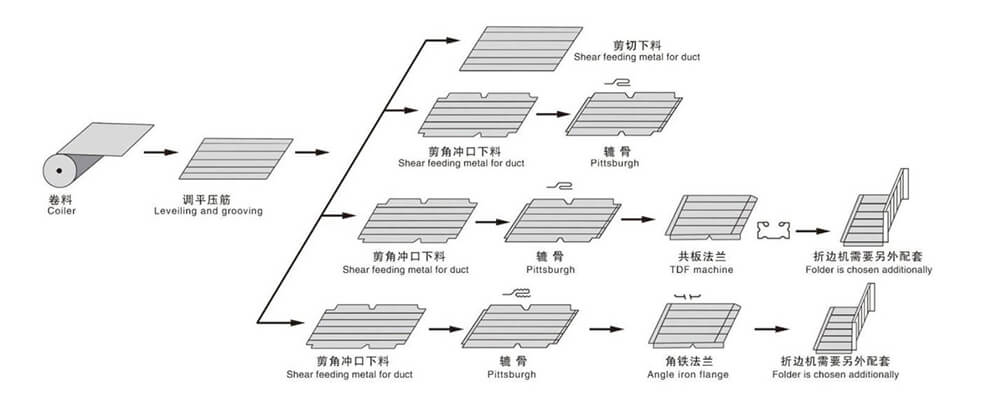

Function

- Unwinding and leveling function to complete the unwinding and leveling of coiled materials.

- Leveling: level the surface of the coil and improve the flatness of the sheet.

- Ribbing: Ribbing is performed on the board to enhance its rigidity and strength.

- Punching corners: punching holes at the corners of the board to facilitate installation and splicing.

- The interface is single-port/double-port processed to achieve single-port or double-port seam forming and improve the connection effect.

- Double-sided angle steel flange processing and forming double-sided angle steel flange structure are suitable for various connection needs.

- Common plate flange processing supports common plate flange forming to meet the requirements of different duct systems.

The main functions of the automatic duct production line 4 include unwinding, leveling, rib pressing, slotting, locking and folding. The main machine of the automatic duct production line 4 is used for leveling, rib pressing, slotting and shearing. All reels are made of bearing steel to extend the service life. Injection holes are used on both sides of the drive shaft to improve the bearing life. It has a material saving mode. The machine can automatically extract metal sheets.

In addition, the automatic duct production line 4 also has a production record function, and the operator can view the production order.

Imported configurations include German Festo cylinders, Beijing Huade and Taiwan hydraulic systems, Taiwan Hiwin linear guides and Schneider electrical systems. The CNC system is Mitsubishi of Japan. At the same time, the basic configuration includes two electric material racks (4 material trays, 5-7 tons per roll), a material rack, a main machine (Line 2 main machine), a robotic arm for grabbing, positioning and conveying, a locking edge forming machine, a duplex TDF flange forming machine, a duplex angle steel flange forming machine, and a computer control system.

Operators can use the automatic duct production line 4 with other square duct equipment (such as hydraulic/pneumatic manual folding machines, hydraulic pneumatic/electric edge sealing machines, corner code punching machines, corner code assembly machines, etc.) to complete the production of the entire duct.

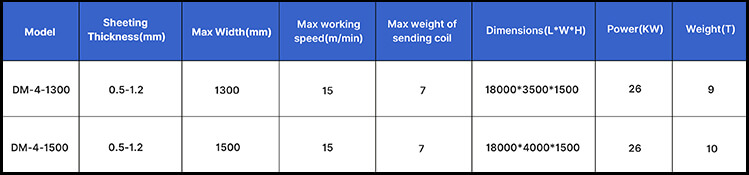

The maximum sheet thickness of Line 4 equipment is 0.2 mm. For sheets, there are two models to choose from, with a maximum width of 1300 mm or 1500 mm. Our company can provide different options according to the different needs of customers. You can contact us at any time via email, mobile phone, WhatsApp, Skype, Facebook, YouTube, etc. If you have any questions about the HVAC duct manufacturing machine, please contact us via WeChat. In addition, we can also provide engineer overseas services if customers need it.

- All rolling reels are made of bearing steel, which increases the service life by more than 5 times.

- The CNC system adds a material saving mode, which can automatically return materials for each task.

- With production memory function, it has the function of querying production orders.

- The latest design effectively solves the problems of plate rolling machine edge impact and excessive number of coils; the three-line bending function can achieve narrow edge curling and stably process 0.5-1.2mm galvanized plates to avoid waste.

- Cylinder imported from Germany festo

- Beijing Huade or hydraulic system from Taiwan

- Japan omron encoder

- Taiwan Hiwin linear guideways

- Taiwan Delta CNC system

- Two electric coil cradles, 4 material trays( 5-7t each roll)

- One rack

- One hose (line 2 host)

- One mechanical arm clutching, locating and transferring platform

- One displacement type locking machine

- One duplex TDF flange forming machine

- One duplex angle steel flange forming machine

- One set of computer controlling system

- Technical Data

- Production Details

Machine Frame

The machine frame adopts welding square steel,annealing treatment and overall processing to ensure the stability and flatness of the frame and processing accuracy.

PLC Control

Use Germany Siemens PLC controller which can accurately control the machining length,particularly suitable for production of ”L” and”口“-shaped pipe with different size.

- Why Choose Us

Industry Experts

Professional HVAC Duct Machines Manufacturer

Perfect After-sales

24-hour after-sales response service

Engineer Overseas Service

Our engineers provide 24/7 on-site technical support

- Frequently Asked Questions

- You can choose the shipping company on your own. Or use our forwarder, we will quote you the CIF price.

- If less than one container,we will choose LCL (less container load), it will be cost-efficiency. If you purchase two and above, we will use 20″, 40″ or HQ container according to the machines size.

DURMAPRESS is a mature brand in China. We have CE, ISO and SGS certification to prove our quality. We welcome your visit, seeing is believing.

- T/T (30% advance payment, and 70% balance paid one week before shipment)

- L/C (100% L/C at sight), this should be negotiated first.

We always prepare stock for our clients. Contact us to learn more details.

Normally 15 days.

- Write Us